Fire-Tested: Sungrow Reinforces BESS Safety with Large-Scale

As energy storage grows in tandem with renewables, fire safety emerges as a critical industry benchmark. Sungrow''s record-breaking burn test sets new safety standards for

Sungrow conducts ''real-world power plant fire'' test

The battery energy storage system (BESS) arm of Chinese solar PV inverter company Sungrow said yesterday (17 November) that the recent test, overseen by standards and certification group DNV, replicated

UL 9540A Test Method for Battery Energy Storage Systems (BESS)

Explore the key updates in UL 9540A:2025, including enhanced testing methods and definitions to improve safety in battery energy storage systems and address fire hazards.

UL 9540A TEST METHOD FOR BATTERY

This test is conducted on the smallest individual battery cell within the Battery Energy Storage System (BESS). A reliable and repeatable method is used to induce thermal runaway inside a pressure vessel.

UL Solutions Enhances Battery Energy Storage

Resulting from a collaboration with the energy storage industry, regulatory authorities and other stakeholders, the test method updates help promote the safe and sustainable growth of the battery

UL 9540A Fire Test Standard for Battery Energy

UL 9540A Fire Test Standard for Battery Energy Storage Systems If a battery system is capable of thermal runaway, the UL 9540A test method will make it happen to show the system''s fire and explosion

Lessons learned from battery energy storage

Full-scale fire testing provides essential understanding of thermal runaway, fire, and explosion hazards associated with LIBs and BESSs. Engineers must then interpret that data to inform the site-specific

FAQ: Texas battery energy storage systems

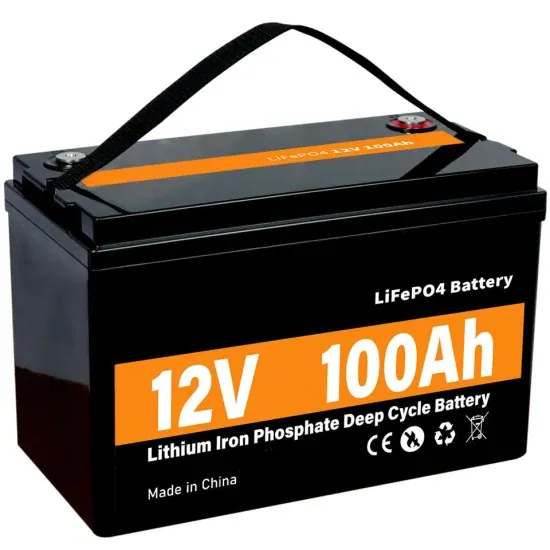

What''s a battery energy storage system? A battery energy storage system (BESS) stores energy in rechargeable batteries. A system typically has battery cells, modules, racks, inverters, and control systems.

UL Solutions Announces Improved Testing

UL Solutions has announced significant enhancements to the testing methods for battery energy storage systems which are critical for storing energy from renewable sources like solar and wind. The new

Explosion protection for prompt and delayed deflagrations in

Explosion hazards can develop when gases evolved during lithium-ion battery energy system thermal runaways accumulate within the confined space of an energy storage

UL expands fire testing for emerging battery technologies

UL Solutions, a global safety science organization, announced it updated its testing methods for battery energy storage systems to include new test methods for non-lithium

Satisfying Explosion Prevention for NFPA 855

These different leak scenarios require a deep understanding of the flammable fluid, storage and operating conditions, and the associated hazards. The critical challenge in designing an explosion prevention

The Evolution of Battery Energy Storage Safety Codes and

75 gigawats of additional deployments between 2023 and 2027 across all market segments,1 with approximately 95% of current projects using Li ion batery technology.2 Incidents involving fire

Designing BESS Explosion Prevention Systems Using CFD Explosion

Lithium-ion based energy storage is one of the leading storage technologies that enables sustainable and emission-free energy. In recent years, due to their power density,

Energy Storage Systems and

Lithium-ion battery ESSs should incorporate adequate explosion prevention protection as required by consensus standards in coordination with the emergency operations plan. Research that

Explosion Control Guidance for Battery Energy Storage

EXECUTIVE SUMMARY grid support, renewable energy integration, and backup power. However, they present significant fire and explosion hazards due to potential thermal runaway

Study on the thermal runaway and explosion characteristics of

The explosion is an essential topic during LIB TR, owing to the accumulation of combustible gases in the confined spaces, such as the battery module or energy storage

Why fire departments and AHJs are pushing back on 9540A

Energy storage systems (ESS) with lithium-based batteries are crucial to the solar industry and the energy transition. Lithium-ion batteries also pose fire risks due to their

UL9540A: 2025 Interpretation of Thermal Runaway Fire Propagation Test

The UL9540A:2025 standard sets a new benchmark for battery energy storage safety, with system-level fire testing, advanced thermal data, and global certification impact.

Assessment of the explosion risk during lithium-ion battery fires

Also, a new parameter to indicate combustion degree including explosiveness and define fire hazard is needed for a battery fire. We explored lithium-ion battery fires in terms

Lithium-ion energy storage battery explosion incidents

Several lithium-ion battery energy storage system incidents involved electrical faults producing an arc flash explosion. The arc flash in these incidents occurred within some

Explosion-Proof Valves in Lithium-Ion Batteries

Learn about the importance of explosion-proof valves in lithium-ion batteries, ensuring safety by preventing pressure build-up and thermal runaway.

Energy Storage System Installation Test Report Now Available

The UL 9540A test standard provides a systematic evaluation of thermal runaway and propagation in energy storage system at cell, module, unit, and installation levels. The data

Battery Energy Storage Systems Explosion Hazards

The paper also discusses the quantity and species of flam-mable gases produced by thermal runaway and demonstrates a simple formula to determine how much energy stored in failing

Siting and Safety Best Practices for Battery Energy Storage

Summary The following document summarizes safety and siting recommendations for large battery energy storage systems (BESS), defined as 600 kWh and higher, as provided by the

Report: Four Firefighters Injured In Lithium-Ion Battery Energy Storage

FSRI releases new report investigating near-miss lithium-ion battery energy storage system explosion. Funded by the U.S. Department of Homeland Security (DHS) and

Test Method for Evaluating Thermal Runaway Fire

UL 9540A: Test Method for Evaluating Thermal Runway Fire Propagation in Battery Energy Storage Systems. The primary measurement is heat release rate using oxygen consumption

UL 9540A Fire Test Standard for Battery Energy

Building and fire codes require testing of battery energy storage systems (BESS) to show that they do not exceed maximum allowable quantities and they allow for adequate distancing between units.

Guide to Storage Safety Certifications | EVLO Energy

As more battery energy storage systems (BESS) are connected to the grid, safety is paramount. That''s why clear safety standards exist for the storage industry; protocols

Battery Pack-Level Fire Safety Proven in SigenStack Stress Test

To rigorously validate the safety performance of its commercial and industrial energy storage system, under extreme fire scenarios, Sigenergy recently completed a full

You might like this video

6 FAQs about [Energy storage battery explosion test]

Do battery energy storage systems need ul 9540a testing?

Building and fire codes require testing of battery energy storage systems (BESS) to show that they do not exceed maximum allowable quantities and they allow for adequate distancing between units. UL 9540A is the consensus test method that helps prove systems comply with fire safety standards.

Why are batteries prone to fires & explosions?

Some of these batteries have experienced troubling fires and explosions. There have been two types of explosions; flammable gas explosions due to gases generated in battery thermal runaways, and electrical arc explosions leading to structural failure of battery electrical enclosures.

What causes large-scale lithium-ion energy storage battery fires?

Conclusions Several large-scale lithium-ion energy storage battery fire incidents have involved explosions. The large explosion incidents, in which battery system enclosures are damaged, are due to the deflagration of accumulated flammable gases generated during cell thermal runaways within one or more modules.

Are battery energy storage systems safe in commercial buildings?

The use of battery energy storage systems (ESS) in commercial buildings is growing rapidly worldwide. For lithium-ion battery and ESS manufacturers, ensuring the safety of these products and systems is crucial, not just for everyday operation but also under demanding conditions and during catastrophic events.

What causes a battery enclosure to explode?

The large explosion incidents, in which battery system enclosures are damaged, are due to the deflagration of accumulated flammable gases generated during cell thermal runaways within one or more modules. Smaller explosions are often due to energetic arc flashes within modules or rack electrical protection enclosures.

How do battery energy storage units interact with power supply and discharge systems?

Interactions with power supply and discharge systems occur via an external Power Conversion System and Energy Management System as shown in Fig. 1. Battery Energy Storage Units have doors for operating and maintenance personnel and for installation and replacement of equipment.