What is liquid-cooled battery cooling? – TYCORUN

The principle of liquid-cooled battery heat dissipation is shown in Figure 1. In a passive liquid cooling system, the liquid medium flows through the battery to be heated, the temperature rises, the hot fluid is

Liquid Cooling Container Energy Storage System Design

Thermal energy storage (TES) for cooling can be traced to ancient Greece and Rome where snow was transported from distant mountains to cool drinks and for bathing water for the wealthy.

Centralized energy storage drawings

Centralized Energy Storage (Liquid Cooled) Product features. Main application areas. The energy storage battery system consists of 20-foot prefabricated pods containing battery systems,

MEGATRON 373KWH-MEGACUBE-Global

Battery Packs utilize 280Ah Lithium Iron Phosphate (LiFePO4) battery cells connected in voltage DC configurations (1331.2V). Liquid cooling is integrated into each battery cabinet using a 50% ethylene glycol water

Battery Energy Storage System Scope Book Rev. 1 7/16/24

1.1 General Owner desires a qualified bidder (Seller) to provide a Baery Energy Storage System (BESS) at Owner proposed locaon. The enre BESS facility shall be controlled by the BESS

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

The layout project for the 5MWh liquid-cooling energy storage cabin is shown in Figure 1. The cabin length follows a non-standard 20''GP design (6684mm length × 2634mm width ×

Energy Storage Pack Drawings: The Blueprint for Efficient Battery

If your drawings can''t survive being coffee-ringed at 3AM crunch time, simplify! The best designs often fit on a napkin – just ask Tesla''s first battery team.

Battery Energy Storage

Active water cooling is the best thermal management method to improve battery pack performance. It is because liquid cooling enables cells to have a more uniform temperature throughout the system whilst using less input

Why Are Liquid Cooling Battery Packs Essential? – XD Thermal

As the demand for efficient and reliable energy storage systems continues to rise, advancements in battery technology are crucial. One such advancement is the liquid cooling battery pack.

How Can Liquid Cooling Revolutionize Battery

With the rapid advancement of technology and an increasing focus on energy efficiency, liquid cooling systems are becoming a game-changer across multiple industries. Among these, Battery Energy Storage Systems

How liquid-cooled technology unlocks the potential

There are numerous causes of thermal runaway, including internal cell defects, faulty battery management systems, and environmental contamination. Liquid-cooled battery energy storage systems provide

CTECHI 5MWh Liquid-Cooled Energy Storage DC

With advanced liquid cooling technology, this energy storage system ensures superior thermal management, enabling enhanced safety, reliability, and

373kWh Liquid Cooled Energy Storage System

The MEGATRONS 373kWh Battery Energy Storage Solution is an ideal solution for medium to large scale energy storage projects. Utilizing Tier 1 LFP battery cells, each battery cabinet is

Battery Energy Storage Systems

Emergency plans/Premises Information boxes (sometimes known as ''Gerda Boxes'') Emergency plans boxes are crucial for ensuring that first responders and maintenance teams have quick access to vital information about the

Centralized energy storage drawings

We are at the forefront of the global renewable energy storage industry, delivering customized Battery Energy Storage System (BESS) containers / enclosures to meet the growing demand

Energy Storage Pack Drawings: The Blueprint for Efficient Battery

The 5 Commandments of Modern Battery Pack Design 1. Thermal Management: Your Battery''s AC Unit Recent projects show liquid-cooled designs reduce hotspots by 40% compared to air

energy storage air-cooled and water-cooled battery boxes

Liquid Cooled Battery V.S. Air Cooled Battery: Key Differences for Commercial Storage heat the battery pack. Liquid-cooled batteries store energy directly in liquid electrolyte solutions

INSTALLATIN MANUAL Energy Storage System

SAVE THESE INSTRUCTIONS : This manual contains important instructions for LG ESS Home 8 (RBA008K0A00) consisting of PCS (RA768K00A10), Battery Module (BPLG004HBG1), and

Liquid Cooling Energy Storage Cabinet Schematic Diagram

Liquid air energy storage (LAES) can offer a scalable solution for power management, with significant potential for decarbonizing electricity systems through integration with renewables.

What is liquid-cooled battery cooling? – TYCORUN

The principle of liquid-cooled battery heat dissipation is shown in Figure 1. In a passive liquid cooling system, the liquid medium flows through the battery to be heated, the

Liquid-Cooled Battery Energy Storage System

High-power battery energy storage systems (BESS) are often equipped with liquid-cooling systems to remove the heat generated by the batteries during operation. This tutorial demonstrates how to define and solve a high

Liquid-cooled energy storage battery charging station

The liquid-cooled energy storage system integrates the energy storage converter, high-voltage control box, water cooling system, fire safety system, and 8 liquid-cooled battery packs into

125KW/233KWh Liquid-Cooling Energy Storage Integrated

The battery container adopts an energy cube structure, and each energy cube is equipped with a water cooler, inverter, and fire control system; the battery module meets the 15-minute quick

USC POWER

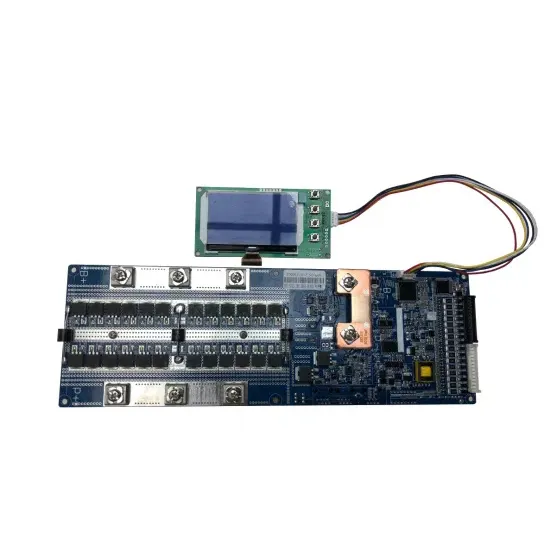

Outdoor Water-Cooled Cabinet The battery rack consists of 8 battery modules and a control box, chiller, fire protection, etc. The battery cell is the most basic battery unit. The BMS is composed of CSC and SBMU. The

Working principle of air-cooled energy storage battery box

Karimi et al. [131] analyzed and assessed the effects of water, silicone oil, and air as cooling media on battery temperature. In contrast to air cooling, water, and silicone oil cooling keep the

Liquid-cooled energy storage battery pack processing

This nanofluid exhibited a 12.6 % reduction in the maximum temperature difference of the battery pack compared to the water-cooled system, albeit with an associated increase in pressure

EGS215 Liquid Cooling Battery Energy Storage System User

Before using this product, please read this manual carefully and operate the energy storage system according to the methods described in this manual to avoid equipment damage or

How Can Liquid Cooling Revolutionize Battery Energy Storage

With the rapid advancement of technology and an increasing focus on energy efficiency, liquid cooling systems are becoming a game-changer across multiple industries. Among these,

Water-cooled energy storage battery

Energy storage liquid cooling technology is suitable for various types of battery energy storage system solution, such as lithium-ion batteries, nickel-hydrogen batteries, and sodium-sulfur

5.01MWh User Manual for liquid-cooled ESS

The energy storage system of this product adopts integrated design, which integrates the energy storage battery cluster and battery management system into a 20-foot container, which

CTECHI 5MWh Liquid-Cooled Energy Storage DC Cabin

The energy storage DC cabin adopts an integrated design, integrating the battery cluster (including battery Packages and high-voltage boxes ), BMS, junction cabinets, fire protection

You might like this video

5 FAQs about [Water-cooled energy storage battery box drawings]

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

How much power does an energy storage container need?

Normal lighting requires a 380/220V power input. Evacuation signs with batteries are provided at exits. 3.8.4.2 Energy storage containers should use rock wool materials for thermal insulation design, featuring insulated wall panels, doors, floor, and roof to prevent the formation of thermal bridges that cause excessive heat loss.

What is a liquid-cooling high voltage box?

The liquid-cooling high voltage box is chiefly installed in the energy storage liquid-cooling battery cluster and manages the power on/off for the battery cluster system. It also connects to battery cluster high voltage and signal output interfaces. The liquid-cooling high voltage box must meet the following requirements:

Does a collection unit need a backup power supply?

3.14.1.2 The collection unit must be equipped with dual power transfer switches and UPS power supply. And the UPS should provide backup power for control and distribution circuit loads in the battery cabin, with a backup time of no less than one hour.