Effect of roll press on consolidation and electric/ionic-path

This study investigated unpressed and pressed electrodes with the synchrotron radiation X-ray computed laminography (CL) technique to clarify the relationship between the

Advanced lithium-ion battery process manufacturing equipment

Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and

Li-Ion battery assembly lines for energy storage

Our expertise encompasses the design and delivery of cutting-edge equipment for assembling lithium-ion and sodium-ion batteries, catering to applications ranging from residential and commercial storage (C&I) to

Energy Storage Roller Press Technology: The Overlooked

Why Your Battery Manufacturing Process Is Costing Millions (And How Roller Press Tech Fixes It) You''ve probably heard about the race for better energy storage solutions. But here''s a dirty

New Yorkers fighting against massive battery

New Yorkers fighting the opening of massive battery energy plants in their neighborhoods have a powerful new ally: US Environmental Protection Administrator Lee Zeldin.

Explore battery roll presses: Key technologies to unlock the future

In today''s lithium battery manufacturing field, the battery roll press (referred to as the roll press) is undoubtedly an indispensable equipment. With its unique rolling process and

battery roller press machine Guide

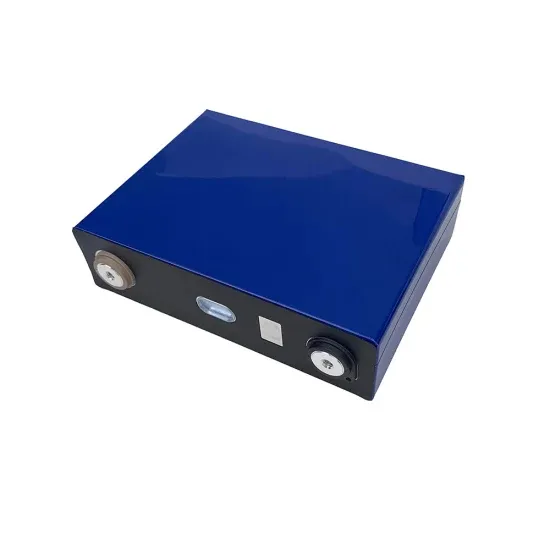

Battery roll press machine, also known as battery sheet press, is a special equipment that compacts the electrode material (positive or negative) of lithium batteries by

Energy Storage Roller Press Suppliers: Powering the Future of

Meet the energy storage roller press – the industrial equivalent of a pancake flipper that squishes battery materials into compact, high-performance layers. These machines are crucial in

200mm Heatable Roller Press Machine for Lab

This hot roller press is especially suitable for thinning and increasing the density of lithium battery electrode sheets of clean energy materials.

Lithium-ion Battery Manufacturing Process

The calendaring process of lithium batteries is an important link in the production process of lithium-ion batteries. By reasonably controlling the calendaring parameters and process

Factory Price Battery Roller Press Machine,Battery Roller Press

The application of lithium battery coating machine With the rapid development of technology, the application of lithium batteries in the energy field is becoming increasingly widespread. From

AME-RPS750 750/850Lithium-ion Battery Roller Pressing and

AME-RPS750/850 automatic roll-to-roll pressing and slitting integrated machine,for lithium battery production line.High efficiency, high precision, and customizable slitting widths.

Energy Storage Roller Press Technology: The Overlooked

But here''s a dirty little secret: 68% of battery production costs come from electrode manufacturing flaws. That''s where energy storage roller press technology becomes a game-changer.

What is lithium battery roller press machine

Through the precise rolling process, it can significantly improve the energy density, charge and discharge efficiency, cycle life and safety and other performance indicators of lithium batteries, laying a solid foundation for the

Lithium Battery Electric Roll Press Machine For Lab Research

Lithium Battery Electric Roll Press Machine For Lab Research Description The equipment is used in the rolling of metal lithium pole pieces in the lithium-sulfur battery industry and the high

Mechanical Structuring of Lithium‐Ion Battery Electrodes Using an

Within this work, an alternative concept for structuring lithium-ion battery electrodes through mechanical embossing in a high-throughput roll-to-roll process is

Energy Storage Roller Press Roller: The Unsung Hero of Modern

Let''s cut to the chase: if you''re writing about energy storage roller press rollers, you''re probably targeting engineers who eat torque calculations for breakfast. These folks want

Energy-Storage.News

Global energy storage technology and energy software services provider Fluence and ACE Engineering have opened a new automated battery storage manufacturing facility in Vietnam''s Bac Giang Province.

Energy storage roller pressing and slitting machine system

Description: This type of roller press is specially used for electric rolling of small lithium electrode sheets, a small amount of precious metal materials such as gold and silver, and non-ferrous

Lithium Battery Rolling Press Machine

The lithium battery electrode is generally compacted by a rolling press machine, as shown in Fig. 1. In this process, the electrodes coated on both sides of the particle coating are fed into the gap between the two rolls, and

Lithium Battery Electric Roll Press Machine For

Lithium Battery Electric Roll Press Machine For Lab Research Description The equipment is used in the rolling of metal lithium pole pieces in the lithium-sulfur battery industry and the high-corrosion industry, with high

An improved ensemble learning model-based strategy for fault

Download Citation | An improved ensemble learning model-based strategy for fault diagnosis of lithium battery double roller press equipment | The production process of

Lithium Ion Battery Manufacturing Process: Roll

The lithium battery rolling process is an important link in the production process of lithium-ion batteries. By reasonably controlling the rolling parameters and process conditions, lithium-ion batteries with

A lithium power energy storage battery multi-electrode rolling

Abstract The invention relates to the technical field of rolling machines, in particular to a multi- electrode rolling machine for lithium -powered energy storage batteries, which includes a base,

Key Equipment for Lithium Battery: Rolling Equipment

The purpose of roller press ing is as follows: The roller pressing process can keep the surface of the electrode smooth and flat, thereby preventing the risk of battery short circuit caused by

Positive Growth Trajectory in Battery Electrode Roller Press

The Battery Electrode Roller Press Machine is a specialized equipment designed for the production of battery electrodes, which are critical components in energy

Rolling Press Machine for Lithium Battery

1.AS-JS Hot roller press machine is a compact hot rolling press machine mainly serves for pressing samples in the lab or other applications in the material research especially for increasing active material density of the

Rollers and FRP winding cores for battery

Battery Production Rollers in battery production For some time now, battery production and the manufacturing of energy storage has posed a rapidly growing dynamic field of technology with global significance.

Battery Energy Storage Systems Report

This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their employees,

Global Lithium Battery Roller Press Machine Sales Market Report

The global Lithium Battery Roller Press Machine market size was US$ 312 million in 2024 and is forecast to a readjusted size of US$ 480 million by 2031 with a CAGR of

Lithium Battery Electrode (Lab) Rolling Press Machine

The battery roller press machine is one of the key processes in the manufacturing process of lithium battery pole pieces. It can increase the energy density and prevent the electrode

Lithium-ion Battery Roller 2025-2033 Overview: Trends,

The global lithium-ion battery roller market is experiencing robust growth, driven by the burgeoning demand for electric vehicles (EVs) and energy storage systems (ESS). The

You might like this video

Related Contents

- Lithium battery energy storage tank production

- Jiang energy storage lithium battery manufacturer

- Lithium titanate household energy storage battery

- Energy storage lithium battery custom manufacturer

- Energy storage lithium battery equalizer supplier

- Energy storage lithium battery call us for consultation