A review of flywheel energy storage systems: state of the art

The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and others.

How do the costs of battery storage systems compare to other energy

In summary, while lithium-ion batteries are widespread and decreasing in cost, other technologies like thermal and compressed air storage offer competitive advantages in

Flywheels in renewable energy Systems: An analysis of their role

This paper presents an analytical review of the use of flywheel energy storage systems (FESSs) for the integration of intermittent renewable energy sources into electrical

Grid-Scale Flywheel Energy Storage Plant

Flywheel systems are kinetic energy storage devices that react instantly when needed. By accelerating a cylindrical rotor (flywheel) to a very high speed and maintaining the energy in

Energy Storage Cost and Performance Database

hydrogen energy storage pumped storage hydropower gravitational energy storage compressed air energy storage thermal energy storage For more information about each, as well as the related cost estimates, please click

Cost optimization of hybrid composite flywheel rotors for energy storage

A novel approach to composite flywheel rotor design is proposed. Flywheel development has been dominated by mobile applications where minimizing mass is critical.

Flywheel Systems for Utility Scale Energy Storage

ABSTRACT The rapid growth of renewable energy sources like photovoltaic solar and wind generation is driving the need for cost-effective energy storage to capture energy during peak

A review of flywheel energy storage systems: state of the art

This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh,respectively. Flywheel energy

Flywheel Storage Systems | SpringerLink

The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic

WhitePaper-Safety of Flywheel Storages Systems

Introduction Flywheel energy storage systems are characterized by a rotor typically operating at relatively high circumferential speeds required for the relevant energy content of the application.

An integrated flywheel energy storage system with

Abstract— The design, construction, and test of an integrated flywheel energy storage system with a homopolar inductor motor/generator and high-frequency drive is presented in this paper.

The development of a techno-economic model for the

After determining the size and capacities of different components, we developed the cost functions for individual pieces of equipment to determine techno-economic

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel energy storage is an exciting solution for efficient and sustainable energy management. This innovative technology offers high efficiency and substantial environmental benefits. Let''s dive into the

thesis.dvi

energy storage rotor to achieve high power density energy storage using low-cost materials. A six- step inverter drive strategy that minimizes inverter VA-rating and enables high frequency

RotorVault Energy Storage Cost Analysis and Flywheel Price

RotorVault Flywheel Cost-Competitive Technology RotorVault''s storage product for data center applications is the most cost-competitive solution offering both backup power for critical IT and

RotorVault Energy Storage Cost Analysis and Flywheel Price

Explore RotorVault''s cost-competitiveness and scalability. A comparative cost analysis with Battery and Flywheel Energy Storage Systems.

Overview of Control System Topology of Flywheel

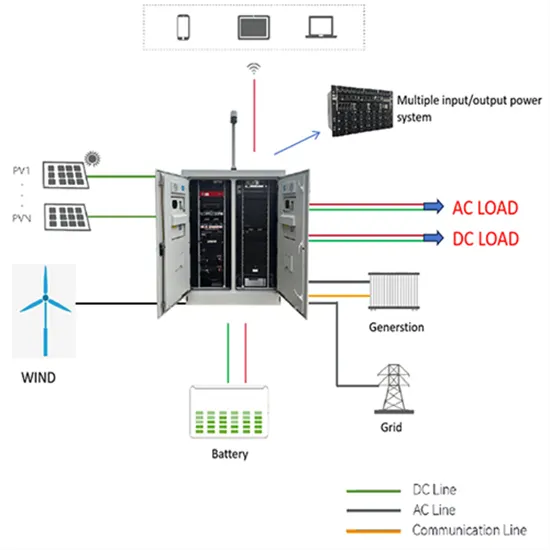

Due to its limited capability and potency in terms of lifespan, cost, energy and power density, and dynamics response, implementing a hybrid energy storage system that combines two or more

Capital cost estimates-flywheel technology.

Download scientific diagram | Capital cost estimates-flywheel technology. from publication: An Evaluation of Energy Storage Cost and Performance Characteristics | The energy storage industry has

Flywheel Energy Storage Costs: Breaking Down the Economics

As global renewable energy capacity surges past 4,500 GW, grid operators face a critical challenge - how to store intermittent solar and wind power effectively.

Composite Flywheels for Energy Storage

Composite flywheels are designed, constructed, and used for energy storage applications, particularly those in which energy density is an important factor. Typical energies stored in a

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

Why Should You Care About Flywheel Project Economics? If you''re reading this, you''re probably wondering: "How much does a flywheel energy storage project ACTUALLY

Flywheel Energy Storage in Action

Explore real-world examples and case studies of flywheel energy storage in renewable energy systems, and learn from the successes and challenges of implementing this

Could Flywheels Be the Future of Energy Storage?

Flywheels are one of the world''s oldest forms of energy storage, but they could also be the future. This article examines flywheel technology, its benefits, and the research from Graz University of

Flywheel Energy Storage System: What Is It and How Does It

In essence, a flywheel stores and releases energy just like a figure skater harnessing and controlling their spinning momentum, offering fast, efficient, and long-lasting energy storage.

flywheel energy storage cost calculation table

A review of flywheel energy storage rotor materials and structures The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy

Overview of Control System Topology of Flywheel Energy Storage

Due to its limited capability and potency in terms of lifespan, cost, energy and power density, and dynamics response, implementing a hybrid energy storage system that

Flywheel energy storage systems: A critical review

The cost invested in the storage of energy can be levied off in many ways such as (1) by charging consumers for energy consumed; (2) increased profit from more energy produced; (3) income increased by

Flywheel energy storage systems: A critical review on

The cost invested in the storage of energy can be levied off in many ways such as (1) by charging consumers for energy consumed; (2) increased profit from more energy

The development of a techno-economic model for the

This study, therefore, focuses on developing a bottom-up techno-economic model to design system components and to evaluate the total investment cost and levelized

Energy Storage Flywheels and Battery Systems

Meeting today''s industrial and commercial power protection challenges. Technological advances in virtually every field of human endeavour are bringing unprecedented demands for clean, uninterrupted power and with

How much does flywheel energy storage

This versatility further substantiates the case for employing flywheel systems in modern energy management strategies. The cost factors influencing flywheel energy storage equipment are multifaceted and

Flywheel vs Battery Energy Storage Cost Analysis

How do flywheel energy storage systems compare to other forms of energy storage (such as batteries) in terms of cost, efficiency, and reliability? calculation Considering

Technology: Flywheel Energy Storage

Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000

You might like this video

6 FAQs about [Flywheel energy storage cost composition table picture]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

How much energy is stored in a composite flywheel?

Typical energies stored in a single unit range from less than a kilowatt-hour to levels approaching 150 kilowatt-hours. Thus, a single composite flywheel can be equivalent, in stored energy, from one to more than 100 automotive batteries. Moreover, in flywheel systems, the stored energy and output power are relatively independent of each other.

What is a composite flywheel?

Composite flywheels are designed, constructed, and used for energy storage applications, particularly those in which energy density is an important factor. Typical energies stored in a single unit range from less than a kilowatt-hour to levels approaching 150 kilowatt-hours.

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.