Structure, Pros and Cons of Square Lithium

Square lithium batteries, also known as prismatic batteries, feature a rectangular shape that allows for efficient space utilization in various applications, particularly in electric vehicles and energy storage

Utility-Scale Battery Storage | Electricity | 2024 | ATB | NREL

The battery storage technologies do not calculate levelized cost of energy (LCOE) or levelized cost of storage (LCOS) and so do not use financial assumptions. Therefore, all parameters are

DOE Explains...Batteries

DOE Explains...BatteriesBatteries and similar devices accept, store, and release electricity on demand. Batteries use chemistry, in the form of chemical potential, to store energy, just like

Prismatic vs Pouch vs Cylindrical Lithium Ion Battery Cell

In this article, we delve into the world of prismatic, pouch, and cylindrical lithium-ion battery cells, comparing their structures, advantages, and use cases. What is a Prismatic

Multifunctional composite designs for structural energy storage

Utilizing structural batteries in an electric vehicle offers a significant advantage of enhancing energy storage performance at cell- or system-level. If the structural battery

Square battery cell module structure and process

The following focuses on the differences between the square battery cell module and the cylindrical battery cell module, and the analysis is mainly from the following aspects.

BATTERY ENERGY STORAGE SYSTEM CONTAINER,

Battery Energy Storage System (BESS) containers are a cost-effective and modular solution for storing and managing energy generated from renewable sources. With their ability to provide

Prismatic Cells: structure, advantages and disadvantages

The structure of the square battery is more straightforward, unlike the cylindrical battery that uses stainless steel with a higher strength as the shell and accessories such as explosion-proof

Square aluminum shell lithium-ion battery energy storage

According to Battery China, Tafel currently produces square aluminum-shell lithium-ion power batteries and energy storage batteries, covering both lithium iron phosphate

Comparison of Structure and Technical

Comparison of Structure and Technical Characteristics between Square and Soft pack Lithium ion Batteries There are currently two main packaging methods for lithium-ion batteries: square packaging and soft packaging.

A review on structure model and energy system design of lithium

Abstract Structure properties of lithium-ion battery determine the specific energy and specific power of renewable energy vehicle and have attracted extensive concerns.

Utility-scale battery energy storage system (BESS)

Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and conversion – and

Battery technologies for grid-scale energy storage

Energy-storage technologies are needed to support electrical grids as the penetration of renewables increases. This Review discusses the application and development

Cylindrical Battery vs Prismatic Battery: Unveiling

However, trade-offs in other aspects such as form factor and cost may apply. How do cylindrical and prismatic batteries contribute to renewable energy storage? Both cylindrical and prismatic batteries play vital roles in

Square Energy Storage Module Composition: Powering

Ever wondered how renewable energy systems store power for cloudy days or windless nights? Enter the square energy storage module composition – the unsung hero of modern power

How should we deal with and handle the problems of square

Square lithium batteries, commonly used in electric vehicles (EVs), energy storage systems (ESS), and portable electronics, offer high energy density and modular design benefits.

Deep Analysis Of Structural Components Design

The fixed structure for square shell battery cells and the manufacturing method for battery module housings have high practical value. This design includes a combination of battery chassis, battery top fixing

Grid-Scale Battery Storage: Frequently Asked Questions

What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage system (BESS) is

Get to Know Square Battery: A Quick Guide

Part 1. What is a square battery? Square batteries, also known as prismatic batteries, are energy storage devices shaped like a square or rectangle. Unlike cylindrical batteries, these are designed to

The basic structure of the square battery

A typical square lithium battery, the main components include: head, shell, positive plate and negative plate, diaphragm of laminated or winding, insulation, safety

What is square energy storage | NenPower

Square energy storage, in contrast, utilizes advanced battery technology designed for compactness and efficiency, making them adaptable to various environments

The basic structure of the square battery

Square battery capacity big, relatively easier cylindrical batteries, in the process of ascension capacity, less restricted.But with the increase of monomer volume, also appeared some problems, such as

A brief introduction to square lithium batteries.

Domestic power lithium battery manufacturers often use square aluminum shell lithium batteries with higher energy density because the structure of square lithium batteries is

New Energy Square Battery Module

The utility model discloses a new energy automobile square battery module end plate, which comprises a substrate, the base plate both sides are provided with first curb plate and second...

Energy storage square, cylindrical, pouch battery, who is stronger?

Square batteries first started from commercial vehicles and were later promoted in the field of energy storage. The capacity of a square battery cell is relatively flexible, so it can

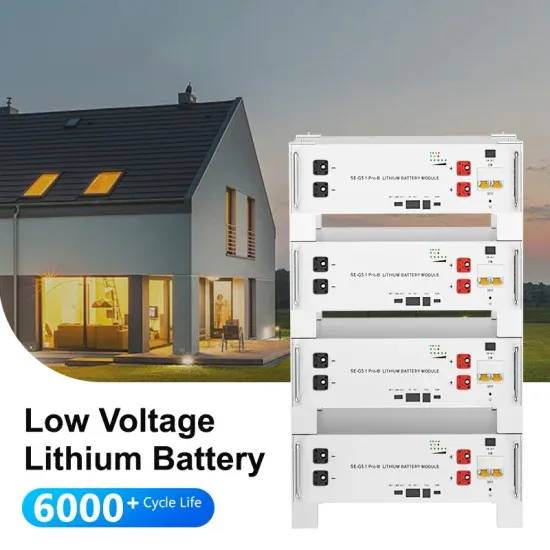

How much does a square energy storage battery

Determining the expense of a square energy storage battery necessitates consideration of a variety of factors.1. Battery specifications, 2. Technology deployed, 3. Manufacturer reputation, 4. Market fluctuations,

Basic structure of square battery

Basic structure of square batteries: a typical square high Lithium ion battery, important composition components include: top cover, shell, positive plate, negative plates, and stacks,

Multifunctional energy storage composite structures with

This work proposes and analyzes a structurally-integrated lithium-ion battery concept. The multifunctional energy storage composite (MESC) structures developed here

Advances in Structure and Property Optimizations of Battery

The intrinsic structures of electrode materials are crucial in understanding battery chemistry and improving battery performance for large-scale applications. This review

Square electric core structure for lithium battery

Referring to fig. 1 to 5, a specific structure of a preferred embodiment of the present invention is shown, which is a square cell structure for a lithium battery, including a housing 10, a...

You might like this video

6 FAQs about [Energy storage square battery structure]

What is a square lithium battery?

Square lithium batteries are prismatic cells designed for high energy density applications, characterized by their rectangular shape that optimizes space utilization. What makes square lithium batteries safer than other types?

What is a square battery?

Square batteries utilize layered electrode stacking instead of spiral winding found in cylindrical cells. This design reduces internal resistance by 15-20% and improves heat dissipation. Their flat surfaces enable tighter packing (90-95% space efficiency vs. 70-80% for cylindrical), critical for compact electronics.

What are the components of a square lithium battery?

Square lithium batteries consist of several key components: Top Cover: Protects internal components. Case: Typically made from aluminum or steel for durability. Positive Plate: Contains active material that facilitates energy storage. Negative Plate: Complements the positive plate in charge and discharge cycles.

Are square batteries a breakthrough in energy density optimization?

The real breakthrough will be solid-state square batteries; we’ve achieved 500 Wh/L prototypes with sulfide-based electrolytes.” — Dr. Elena Voss, Battery Technology Director at PowerCell Innovations Square batteries represent the pinnacle of energy density optimization through geometric innovation.

How do square batteries work?

Modern square batteries use lithium nickel manganese cobalt oxide (NMC) cathodes (60% market share) or lithium iron phosphate (LFP) for stability. Aluminum laminated film (95μm thickness) forms the pouch casing instead of metal cans. Anodes combine graphite with 5-10% silicon oxide for increased capacity.

How many square cells are in a battery pack?

Electric vehicles like Tesla Model 3 employ 4,416 square lithium cells in structural battery packs. Medical devices (85% of hearing aids), drones, and renewable energy storage systems also prioritize them for space-constrained, high-energy-density requirements. Emerging uses include foldable electronics and grid-scale storage modules.