Container Yard Capacity Calculator & Formula Online Calculator

Container yard capacity calculation is a crucial tool for logistics and warehouse management. It helps in estimating the total number of containers that can be stored within a

Container energy storage energy calculation

How is energy consumption calculated in a container terminal? Energy consumption was calculated based on utility data as well as fuel and electricity consumptions for each container

Calculation method of electricity consumption of energy

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Key Performance Indicators for Battery Energy

Discover the seven essential performance metrics—capacity, power rating, efficiency, cycle life, cost, response time, and density—that define a high-performing Battery Energy Storage

Understanding Battery Energy Storage System

Selection of battery type BESS can be made up of any battery, such as Lithium-ion, lead acid, nickel-cadmium, etc. Battery selection depends on the following technical parameters: BESS Capacity: It is the

Energy storage container heat calculation

Thermal energy storage of sensible heatrelies on stored energy or the release that occurs when a specific substance differs its temperature under the exact final and initial chemical structure. 20

Container energy storage intensity calculation formula

intensity Given the rising demand for energy and the escalating environmental challenges, energy storage system container has emerged as a crucial solution to address The Carbon Intensity

BESS Methodology

Abstract This methodology describes the process to design the layout of a battery energy storage system in the software pvDesign. The authors of this methodology have proposed the following

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections

Estimation of underground hydrogen storage capacity in depleted

The established model provides important references for calculating the storage capacity of gas storage facilities in oil and gas reservoirs with edge and bottom water as well

HOW TO DESIGN A BESS (BATTERY ENERGY

The design of a BESS (Battery Energy Storage System) container involves several steps to ensure that it meets the requirements for safety, functionality, and efficiency.

Container energy storage energy calculation formula

Energy Capacity (MWh) indicates the total amount of energy a BESS can store and subsequently deliver over time. It defines the duration for which the system can supply power before

Simulation analysis and optimization of containerized energy storage

In this paper, the airflow organization distribution of the containerized energy storage battery thermal management system is evaluated by considering the heat exhaust

CONTAINER ENERGY STORAGE POWER CALCULATION

Energy storage density efficiency calculation formula When discussing the chemical energy contained, there are different types which can be quantified depending on the intended

BESS Container Sizes: How to Choose the Right

Not sure which BESS container size fits your project? Discover the differences between 20ft, 40ft, and modular systems—plus expert tips to help you choose the right solution. Start planning today with

Container Design for Battery Energy Storage

Learn how we optimized design of a battery storage system container to reduce weight, ensure structural integrity, and achieve efficient thermal regulation.

Energy Storage Feasibility and Lifecycle Cost Assessment

To evaluate the technical, economic, and operational feasibility of implementing energy storage systems while assessing their lifecycle costs. This analysis identifies optimal storage

Understanding MW and MWh in Battery Energy

In the context of a Battery Energy Storage System (BESS), MW (megawatts) and MWh (megawatt-hours) are two crucial specifications that describe different aspects of the system''s performance.

Calculation of heat capacity of energy storage container

In this paper, the heat dissipation behavior of the thermal management system of the container energy storage system is investigated based on the fluid dynamics simulation

Shipping Container Energy Storage System Guide

Explore innovative shipping container energy storage systems for sustainable, off-grid power solutions. Harness renewable energy storage effectively.

Load Calculator App | SeaRates Load Calculator

SeaRates cargo loading software to optimize container loading capacity online. Try the container loading calculator to estimate Pallet Load and cargo dimensions to make your shipments safe and cost-profitable.

Performance and Health Test Procedure for Grid Energy

Abstract— A test procedure to evaluate the performance and health of field installations of grid-connected battery energy storage systems (BESS) is described. Performance and health

EnSights: BESS size calculator enables

EnSights BESS calculator''s visualisation of daily interaction between an energy storage system and co-located solar PV. Image: EnSights. Renewable energy portfolio

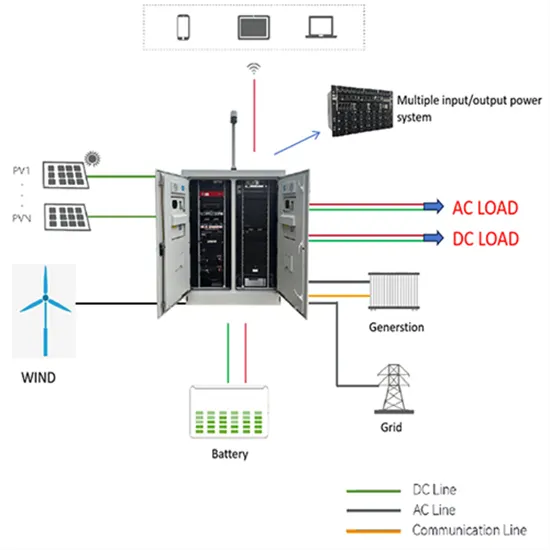

Design of Cold Chain Container Energy Storage and Conversion

Design of Cold Chain Container Energy Storage and Conversion System Based on Modularization Published in: 2021 IEEE 5th Conference on Energy Internet and Energy

How many kilowatts of energy can a container store?

The capacity of energy storage containers is influenced by several critical factors, including container type, battery technology, and environmental conditions. The container''s design directly influences how

Understanding Energy Storage: Power Capacity vs. Energy Capacity

Discover the key differences between power and energy capacity, the relationship between Ah and Wh, and the distinctions between kVA and kW in energy storage

Energy storage container heat calculation

What is thermal energy storage? Thermal energy storage of sensible heat relies on stored energy or the release that occurs when a specific substance differs its temperature under the exact

Calculation of heat capacity of energy storage container

Thermal energy storage in the form of sensible heatrelies on the specific heat and the thermal capacity of a storage medium,which is usually kept in storage tanks with high thermal

Understanding Power and Energy in Battery

Learn the key differences between power and energy in BESS. Discover how these concepts impact performance, sizing, and design of battery energy storage systems.

Warehouse Capacity Calculator & Formula Online Calculator Ultra

Accurate calculation of warehouse capacity helps in planning inventory levels, avoiding overstocking or understocking, and maximizing storage efficiency. How can I improve

Simulation analysis and optimization of containerized energy

In this paper, the airflow organization distribution of the containerized energy storage battery thermal management system is evaluated by considering the heat exhaust

Rated Energy Storage Capacity is the total amount of stored

Firm Capacity, Capacity Credit, and Capacity Value are important concepts for understanding the potential contribution of utility-scale energy storage for meeting peak demand. Firm Capacity

Integrated cooling system with multiple operating modes for

In Shanghai, the average energy consumption of the proposed container energy storage temperature control system is about 3.3 %, while the average energy consumption of

You might like this video

6 FAQs about [Container energy storage capacity calculation]

What is a battery energy storage container?

A well-structured battery energy storage container optimizes internal airflow, reduces cable loss, and ensures better thermal control. For example, two 40ft BESS containers with the same capacity can perform very differently depending on their internal configuration.

How do I choose a containerized energy storage system?

Choosing between these sizes depends on project needs, available space, and future scalability. Regardless of format, each containerized energy storage system includes key components such as battery racks, BMS, EMS, cooling, and fire protection.

What size battery energy storage container do I Need?

From small 20ft units powering factories and EV charging stations, to large 40ft containers stabilizing microgrids or utility loads, the right battery energy storage container size can make a big difference.

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

What is power capacity & energy capacity?

A fundamental understanding of three key parameters—power capacity (measured in megawatts, MW), energy capacity (measured in megawatt-hours, MWh), and charging/discharging speeds (expressed as C-rates like 1C, 0.5C, 0.25C)—is crucial for optimizing the design and operation of BESS across various applications.

How do I choose a Bess containerized battery energy storage system?

These containerized battery energy storage systems are widely used in commercial, industrial, and utility-scale applications. But one of the most important factors in choosing the right solution is understanding BESS container size — and how it impacts performance, cost, and scalability.