Complete Guide to Lithium Battery Protection Board

In this article, we will explore what a battery PCB board is, how it works, the key differences between related components like PCM and BMS, and the importance of using a

13S BMS 48V 50A Li-ion PCB Protection Board

13S BMS 48V 50A Li-ion PCB Protection Board with Balance Wire and NTC,Ten Functional protections, Common Port, for Solar Energy Storage, Balance Car Lithium-ion Battery Pack (13S 48V 50A)

What is a Lithium Ion Battery Protection IC?

The lithium battery IC is an integrated circuit—or chip—mounted on the protection board and tasked with preventing adverse situations. It works alongside other components, such as transistors,

DALY BMS 8S 24V 100A LiFePO4 Battery Protection Module PCB Protection

About this item [DALY BMS]Overcurrent,Overcharge,Overdischarge,Short circuit, Temperature protection.DALY BMS maximizes optimizes the lithium battery performance, and extends the battery lifetime to a large extent. [Double Protection]

BMS Overcurrent Protection: Indispensable for

MOKOEnergy''s BMS and Battery Board Solution is the Best in Over-current Protection Overcurrent protection refers to the lithium battery in the power supply to the load, the current will change with the

A Guide to Designing A BMS Circuit Diagram for Li

I have 3 of these circuit units collected on a single board, which lets me charge 3 lithium-ion battery banks simultaneously. In theory, you could have any number of these circuit units. The board has a trimmer

Capacitor Deep Dive: Circuit Protection, Filtering, Storage

Explore the role of capacitors in circuit protection, filtering, and energy storage. Learn how capacitors work in both AC & DC circuits for various applications.

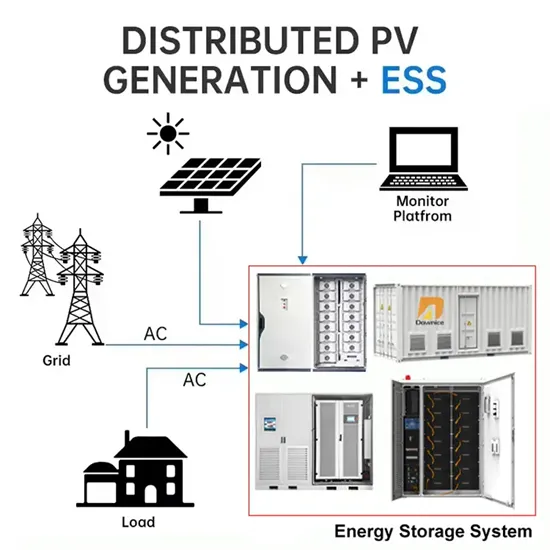

Solar Energy Storage System Battery Protection Board Selection

Ternary lithium battery protection board: Ternary lithium batteries have high energy density, and the protection board needs to set a steep voltage protection point (such as

What is BMS (Battery Management System) Boards

The protection circuit, or battery protection board, is particularly critical. It is a circuit board containing control ICs, MOS (Metal Oxide Semiconductor) switches, resistors, and

What is a Battery PCB? Protection Circuit Board

Explore battery PCB protection boards for Li-ion & Li-Po batteries at FS Circuits. Prevent overcharging, over-discharging, and short circuits for safer battery performance.

Key Differences Between BMS and Lithium Battery Protection Board

In the wide application of Li-ion batteries, whether it is small portable devices or large-scale energy storage systems, safety and performance are always the key issues. For this reason,

Why Your Energy Storage Battery Needs a Protection Circuit

From Arctic cold to desert heat, modern energy storage protection circuits need to handle it all. NASA''s lunar battery systems use self-warming circuits that sip power to

PCB Batteries: Small Digital Battery Protection Circuit Boards

Key Components of PCB Batteries Battery Cells: PCB batteries typically use lithium-ion or lithium-polymer cells due to their high energy density and lightweight nature.

How many A storage battery protection board | NenPower

To truly grasp the significance of protection boards in battery storage, it''s advantageous to explore what a storage battery entails. Batteries serve as devices that convert

BMS Protection Board Selection Guide

By understanding key factors such as battery type, voltage requirements, battery balancing function, protection function, temperature management, etc., you can choose the

Lithium Battery Protection Board (PCB) and Battery Management

To ensure the safety, efficiency, and longevity of lithium battery systems, the Lithium Battery Protection Board (PCB) and the Battery Management System (BMS) are

How about the energy storage battery protection board

Energy storage battery protection boards play a crucial role in enhancing longevity and safety, providing essential management features to prevent overcharging, deep

Understanding Lithium Battery Protection and Applications of 48V

To safeguard against these risks, lithium battery components are typically equipped with protection circuits and current protectors. Lithium Battery Protection Functions The protection

BMS Short Circuit Protection for Battery Packs

Lithium-ion batteries provide high energy density and efficient power for electric vehicles, energy storage systems, and other applications. However, battery short circuits will carry risks – especially

Lithium Battery Protection Board (PCB) and Battery Management

Lithium batteries play a vital role in modern electric vehicles (EVs), energy storage systems (ESS), and portable devices. To ensure the safety, efficiency, and longevity of

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

For a single cell, Table 6 shows a voltage range from 2.75 to 4.2 V, a charging rate up to 2600mA (1C) and discharging rate up to 5200mA (2C). For multiple-cell packs, the guidelines for

INSTALLATION OF ENERGY STORAGE LITHIUM

A lithium battery protection board typically includes various essential components like voltage regulators,transistors,resistors,and microcontrollers. The protection circuit ensures the voltage

Battery PCB: Design, Manufacturing and

Protection and Safety in Battery PCB Design As Battery PCBs are becoming a central component in modern systems such as electric vehicles, consumer electronics, and energy storage solutions, their safety

What is a Battery PCB? Protection Circuit Board for Li-ion & Li-Po

Explore battery PCB protection boards for Li-ion & Li-Po batteries at FS Circuits. Prevent overcharging, over-discharging, and short circuits for safer battery performance.

LISHEN | LISEHN Battery | Lithium Battery | Li-ion Battery | EV Battery

There are some significant differences between lithium-ion battery protection boards and BMS (battery management system) in terms of function and role, although they are

What is a BMS Board? The Key to Efficient Battery Management

1. Introduction to BMS Boards A Battery Management System (BMS) board is a critical component in modern energy storage systems, ensuring optimal performance, safety,

Battery protection units (BPU) | Infineon Technologies

A battery protection unit (BPU) prevents possible damage to the battery cells and the failure of the battery, enhancing the useful operating life of lithium-ion batteries by protecting the battery

Solar Energy Storage Battery Circuit Protection Board Pcb ESS

Solar Energy Storage Battery Circuit Protection Board Pcb ESS BMS LiFePO4 16S 8S 15S 100A 150A 250A Smart Software ESS BMS

A Comprehensive Guide to Choosing Lithium Battery Protection Boards

The protection board is the "safety manager" of lithium batteries. Its main function is to prevent overcharging, overdischarging, overcurrent and short circuits, and to balance the voltage of the

DALY BMS 8S 24V 100A LiFePO4 Battery Protection Module PCB Protection

About this item [DALY BMS]Overcurrent,Overcharge,Overdischarge,Short circuit, Temperature protection.DALY BMS maximizes optimizes the lithium battery