Liquid Cooling in Energy Storage | EB BLOG

Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance benefits driving this

classification of liquid cooling pipelines in energy storage industry

Optimization of data-center immersion cooling using liquid air energy storage At this point, the minimum outlet temperature of the data center is 7.4 °C, and the temperature range at the data

U.S. Codes and Standards for Battery Energy

This document provides an overview of current codes and standards (C+S) applicable to U.S. installations of utility-scale battery energy storage systems. This overview highlights the most impactful documents and is not intended

Liquid Cooling Integration and Logistics White Paper

Liquid cooling using cold plates cooling technologies has been the focus of many technology papers and industry guidelines. It is known that liquid cooling is an efficient and effective

How Is The Design Of The Energy Storage Liquid

Firstly, the liquid cooling joint adopts a car grade leak proof cooling pipeline quick plug joint, which can ensure that the risk of liquid leakage is minimized during the operation of the energy storage system.

Energy storage system pipeline design specifications

Compliance Guide (CG) covers the design and construction of stationary energy storage systems (ESS), their component parts and the siting, installation, commissioning, operations,

Container energy storage liquid cooling pipeline

The introduction of liquid-cooled ESS container systems demonstrates the robust capabilities of liquid cooling technology in the energy storage sectorand contributes to

Development of Standards for Hydrogen Storage and

Standards for hydrogen piping and pipelines are only published by CGA and ASME. Chinese GB standards are mainly focused on general design and safety, gaseous hydrogen receptacles

Liquid cooling design requirements for energy storage systems

While liquid cooling systems for energy storage equipment, especially lithium batteries, are relatively more complex compared to air cooling systems and require additional components

Principles of liquid cooling pipeline design

This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition and design of the liquid cooling pipeline.

Liquid cooling pipeline design for energy storage enterprises

What is a liquid cooling pipeline? Liquid cooling pipelines are mainly used to connect transition soft (hard) pipes between liquid cooling sources and equipment, between equipment and

(PDF) Simulation Study on Liquid Cooling of

Purposing to the thermal profile management of a typical format 21700 lithium-ion battery cell, this study develops a cellular liquid cooling jacket to meet their cooling requirements.

liquid cooling energy storage system

Liquid cooling energy storage system management and control The control system gathers pressure and temperature data from sensors to regulate the operating speed, position, and current of the actuators, thereby ensuring

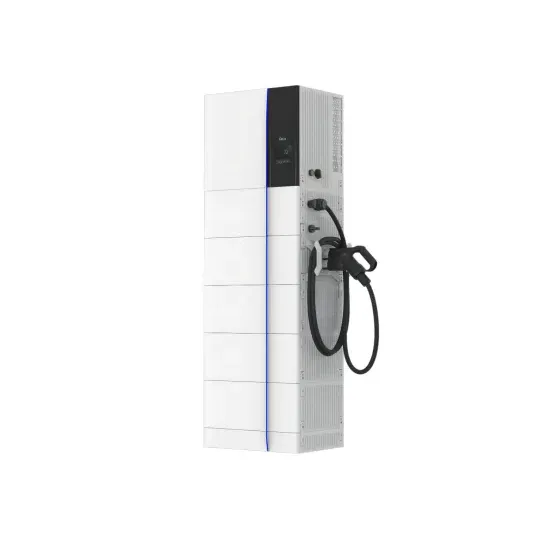

Containerized Liquid Cooling ESS VE-1376L

Vericom energy storage cabinet adopts All-in-one design, integrated container, refrigeration system, battery module, PCS, fire protection, environmental monitoring

Cape Town 5MW/10MWh Battery Energy Storage System

This solution adopts the thermal management form of liquid cooling and liquid heating, through the precise design of the module cold plate, Passive flow balance design of three-stage

energy storage liquid cooling pipeline manufacturer ranking

Details and Price about Plastic Coolant Pipe Assembly Liquid Cooling Pipeline from Plastic Liquid Cooling Pipeline for Energy Storage Equipment - Shijiazhuang Standards Rubber Products

Modeling and analysis of liquid-cooling thermal management of

A self-developed thermal safety management system (TSMS), which can evaluate the cooling demand and safety state of batteries in real-time, is equipped with the

Liquid cooling energy storage system pipeline

This article explores the top 10 5MWh energy storage systems in China, showcasing the latest innovations in the country''''s energy sector. From advanced liquid cooling technologies to high

Development of energy storage liquid cooling pipeline system

What is a liquid cooling pipeline? Liquid cooling pipelines are mainly used to connect transition soft (hard) pipes between liquid cooling sources and equipment, between equipment and

Energy Storage System Cooling

All the challenges and issues with respect to compressor-based cooling systems - power, efficiency, reliability, handling and installation, vibration and noise, separate heating and

Understanding battery liquid cooling system

The energy storage liquid cooling system mainly includes liquid cooling plate, liquid cooling host, pipelines, joints, evaporator, etc. The liquid-cooled host uses the power of the compressor to open up the

design specification requirements for energy storage liquid cooling

Principles of liquid cooling pipeline design This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection and

Liquid Cooling Energy Storage System

This manual is an integral part of the intelligent all-in-one liquid cooling energy storage system. It describes the transportation, storage, installation, electrical connection, commissioning,

372kWh Liquid Cooling High Voltage ESS | GSL ENERGY

372kWh liquid-cooling high Voltage Energy Storage System (372kWh Liquid Cooling BESS Battery) Independent temperature control adoption of centralized refrigeration, multistage

Liquid Cooling Energy Storage Cabinet Pipeline Design

This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection and design of the liquid cooling pipeline.

Liquid-cooled Energy Storage Cabinet

Commercial & Industrial ESSExcellent Life Cycle Cost • Cells with up to 12,000 cycles. • Lifespan of over 5 years; payback within 3 years. • Intelligent Liquid Cooling, maintaining a temperature

Study on uniform distribution of liquid cooling pipeline in container

Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Emergence and Expansion of Liquid Cooling in Mainstream

Liquid-only processor chips are currently available, and more are coming in the near future. There are many who wish to put off the introduction of liquid cooling into the data center due to its

design standard requirements for energy storage cooling pipelines

The Canada Energy Regulator (CER) provides a list of codes, standards and specifications that apply to the design, construction, operation and maintenance of pipelines and facilities under

Frontiers | Research and design for a storage liquid

Based on the device status and research into industrial and commercial energy storage integrated cabinets, this article further studies the integration technology of high energy density industrial and commercial

5.01MWh User Manual for liquid-cooled ESS

The energy storage system of this product adopts integrated design, which integrates the energy storage battery cluster and battery management system into a 20-foot container, which

Liquid Cooling in Energy Storage | EB BLOG

Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance benefits driving this technological shift.

You might like this video

6 FAQs about [Energy storage liquid cooling pipeline standards]

What is energy storage liquid cooling system?

Energy storage liquid cooling systems generally consist of a battery pack liquid cooling system and an external liquid cooling system. The core components include water pumps, compressors, heat exchangers, etc. The internal battery pack liquid cooling system includes liquid cooling plates, pipelines and other components.

What is a liquid cooling pipeline?

Liquid cooling pipelines are mainly used to connect transition soft (hard) pipes between liquid cooling sources and equipment, between equipment and equipment, and between equipment and other pipelines. Pipe selection affects its service life, reliability, maintainability and other properties.

What is the internal battery pack liquid cooling system?

The internal battery pack liquid cooling system includes liquid cooling plates, pipelines and other components. This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection and design of the liquid cooling pipeline.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is energy storage cooling?

Energy storage cooling is divided into air cooling and liquid cooling. Liquid cooling pipelines are transitional soft (hard) pipe connections that are mainly used to connect liquid cooling sources and equipment, equipment and equipment, and equipment and other pipelines. There are two types: hoses and metal pipes.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.