Energy Storage Welding Machines: The Future of Precision

By drawing energy during off-peak hours and operating from stored power during demand spikes, they''re essentially acting as distributed energy resources (DERs). A 2025 MIT Energy Lab

The function of energy storage welding gun

This will require the pulsed power system to provide more than 100 MJ of energy into the rail gun chamber at a time. they can also be used in electromagnetic forming, hydroelectric forming,

Understanding Spiral Welded Pipes for Oil & Gas

The spiral welding process actually becomes more cost-effective as diameter increases, making it particularly advantageous for large-diameter applications. Q: How do spiral welded pipes compare to

DOE Awards $28 Million for Wind Energy

Keystone Tower Systems of Westminster, Colorado will demonstrate on-site spiral welding of a 160-meter wind turbine tower, as well as installation of up-tower components with a tower-mounted self-hoisting

Analysis of fatigue fracture mechanism of laser spiral welding of

This paper investigates the relationship between weld quality, influencing factors, microstructure and mechanical properties of laser spiral dissimilarity welding of 6082 high

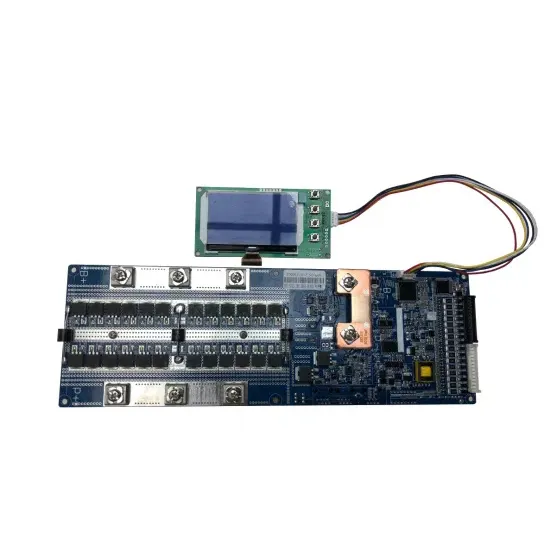

What are the energy storage welding gun

1. Energy storage welding guns comprise several essential components, including: 1. A capacitor bank that stores energy for discharge during welding, 2. A control circuit that regulates the electrical flow, 3. A

What does energy storage welding gun mean? | NenPower

Energy storage welding guns represent a crucial innovation in the welding industry. 1. Such devices integrate advanced technology for adequate power storage, 2.

Energy Storage Welding Guns: The Future of Precision Joining

Ever wondered how your smartphone survives that accidental coffee bath or why electric car batteries don''t melt into modern art during production? Meet the energy

What are energy storage welding | NenPower

Energy storage welding incorporates advanced technologies to utilize energy generated from various renewable sources effectively. 1. It enhances efficiency across various sectors, 2. It integrates seamlessly

The future of energy storage spiral welding gun

As the photovoltaic (PV) industry continues to evolve, advancements in The future of energy storage spiral welding gun have become critical to optimizing the utilization of renewable

How are energy storage welding nails processed? | NenPower

Energy storage welding nails are processed through several intricate stages that ensure their efficiency and effectiveness in various applications. 1. Material Selection plays a

Development of a flywheel energy storage-based welding system

Due to the novel storage type in this field of application, the whole power electronic system needs to be redeveloped. To find the best concept, a detailed comparison of several topologies has

An Electromagnetic Railgun Design and Realization for an

Abstract: This work reports on how a team of four undergraduate students at the United States Air Force Academy designed, built, and tested a desk-top railgun for a year-long senior design

What is the power of energy storage welding? | NenPower

1. The power of energy storage welding is characterized by significant advancements in efficiency, versatility, and sustainability.2. This innovative technology utilizes

EERE SUCCESS STORY—HOW SPIRAL WELDING IS

The future of energy storage spiral welding gun Energy storage is a potential substitute for, or complement to, almost every aspect of a power system, including generation, transmission,

What are the characteristics of energy storage welding gun

An energy storage welding gun is an advanced tool designed to optimize the welding process by storing energy for immediate use when required. Unlike traditional models

Application status of energy storage stud welding technology

The equipment consists of a control unit, a welding hand gun, and all necessary inter- connecting cables. THE PROCESS Capacitor Discharge (CD) stud welding is a form of welding in which

What are the characteristics of energy storage welding gun

Energy storage welding guns exhibit distinctive characteristics that contribute to their effectiveness and usability in various applications. 1. Innovative Design: Energy storage

The future of energy storage spiral welding gun

Twists of Strength: Exploring Spiral Welding Techniques Types of Materials Suitable for Spiral Welding. Spiral welding is adaptable to a wide range of materials, including carbon steel,

the development of energy storage spiral welding gun

Here''s some videos on about the development of energy storage spiral welding gun How are Bullets and Cartridges Made? | Development of the In this video, we dive deep into

An Automatic Welding Robot for the Roof of Spiral

A spiral steel silo has become the preferred choice for building steel silos because of its short construction period, low cost, and high strength. Owing to the harsh outdoor welding conditions of the spiral

The future of energy storage spiral welding gun

Energy storage is a potential substitute for, or complement to, almost every aspect of a power system, including generation, transmission, and demand flexibility. Storage should be co

What is the principle of energy storage spot welding

1. Energy storage spot welding is a process that utilizes stored energy to create welds, characterized by rapid energy release and heat generation, ensuring localized heating, resulting in a strong bond

Development of energy storage technology

Chapter 1 introduces the definition of energy storage and the development process of energy storage at home and abroad. It also analyzes the demand for energy

the development of energy storage spiral welding gun

Keystone Tower Systems and GE Renewable Energy announced a major milestone in the development of tapered spiral welding with the installation of the first commercial spiral-welded

The Top Advantages of C3 Energy Storage Stud Welding Guns

Ever wondered why C3 energy storage stud welding guns are suddenly the talk of every manufacturing floor? Whether you''re in automotive assembly, shipbuilding, or crafting sleek

71245 papers.pdf

Experiments on A6 Relativistic Magnetron Fed by a Solid Cylindrical Cathode: ~350 MW of High-Power Microwaves at ~4.675 GHz (2π-mode) During ~25 Ns for Directed Energy (DE) and Non-

What is energy storage welding nail | NenPower

The operation of energy storage welding nails is predicated on advanced tools and techniques that allow for their unique functionality. The process generally involves a

Japanese Energy Storage Welding Gun Production: Innovations

If you''re in automotive manufacturing, robotics, or renewable energy, you''ve probably heard whispers about Japanese energy storage welding guns. But let''s be

Energy Storage Welding Guns: The Future of Precision Joining

Meet the energy storage welding gun – the unsung hero behind leak-proof electronics and ultra-durable auto parts. Let''s dive into why this tech is revolutionizing

What does energy storage welding gun mean? | NenPower

Energy storage welding guns signify a transformative advancement in the welding landscape. With their capacity for improved efficiency, reduced energy consumption,

The future of energy storage spiral welding gun

Keystone Tower Systems and GE Renewable Energy announced a major milestone in the development of tapered spiral welding with the installation of the first commercial spiral-welded

The future of energy storage spiral welding gun

Twists of Strength: Exploring Spiral Welding Techniques Types of Materials Suitable for Spiral Welding. Spiral welding is adaptable to a wide range of materials, including carbon steel,