Hygreen Energy Launches New AEM Electrolyzer

Designed to combine efficiency, safety, and versatility in a turnkey solution, Hygreen Energy''s new AEM electrolyzers are customizable up to 100 Nm 3 /h (500 kW) of hydrogen generated, and operate across a

Bramble launches £1.5m hydrogen project with

Bramble Energy''s PCBEL technology has met the Clean Hydrogen Partnership''s 2030 targets for performance and critical raw material content. It utilises the printed circuit board supply chain, achieving

Global AEM Water Electrolyzer Market 2024 by Manufacturers,

Consumer Analysis: Report covers data on consumer behaviour, preferences, and attitudes towards AEM Water Electrolyzer This may involve surveys, interviews, and

World-First 5MW AEM Electrolyser to deliver cheaper green hydrogen

As an important part of the global energy transition, the interest in hydrogen as a decarbonisation tool is high, but the cost of hydrogen has been a hurdle to widespread

McPhy: clean hydrogen production and distribution equipment

As a leading supplier of hydrogen production and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Hygreen Energy Launches New AEM Electrolyzer

Hygreen Energy announces the introduction of its first-ever Anion Exchange Membrane (AEM) electrolyzer system. This new electrolyzer broadens Hygreen Energy''s product portfolio beyond its flagship alkaline

Electro Power Cell Energy Technology (Shanghai)

In the hydrogen energy sector, we focus on PEM water electrolysis equipment, AEM electrolyzer development, green methanol equipment, methanol reforming for hydrogen production, and fuel cell CHP

AEM: Modular & Cost-Effective Hydrogen Production

Learn about HYDGEN''s AEM electrolyzers: cost-effective, scalable green hydrogen solutions with high efficiency for sustainable energy.

Replacing Traditional Energy with Hydrogen Energy

AEM Water Electrolyser AEM water electrolyser is a new type of electrolyser that uses advanced anion exchange membrane (AEM) technology to split water into hydrogen and oxygen. Compared with traditional electrolysers,

Association of Equipment Manufacturers Presentation

AEM is the leading organization in North America advancing construction and agriculture equipment manufacturers and their value chain partners in the global marketplace. In enabling

Enapter begins offering its AEM hydrogen

Enapter, a German-Italian-Thai manufacturer of anion-exchange membrane (AEM) electrolysers, has begun selling its equipment with lithium-ion batteries to optimise the input of variable renewable

Home

More than 12,000 Enapter AEM Stacks produce green hydrogen worldwide, making the most of intermittent renewables with best-in-class efficiency, reactivity and operational flexibility.

E-FUEL_AEM electrolysis water hydrogen production equipment

The company is committed to becoming the world''s leading hydrogen energy equipment technology service company.The core products are water electrolysis hydrogen

AEM Water Electrolyzer for Hydrogen Production from

Increases electrolyzer efficiency Reduces transmission costs Reduces hydrogen storage costs Develop high-performance oxygen evolution reaction (OER) selective electrodes and modify

Ecolectro and Re:Build partner to scale renewable hydrogen in

Why on-site renewable hydrogen matters Hydrogen transportation and storage costs can add US$5 – 7/kg, increasing expenses by over US$1 million annually for large users,

Efficient AEM Modular Hydrogen Production

This system is capable of producing high-purity hydrogen through water electrolysis, making it ideal for various industrial applications, including fuel cells, chemical production, and energy storage.

E-FUEL_AEM electrolysis water hydrogen production equipment

AEM Electrolyser is a small-scale hydrogen production system independently developed and designed by E-FUEL Technology, which integrates hydrogen production, gas

Pilot equipment is four times larger than any

US start-up backed by Shell, Amazon and Nasa unveils ''first ever industrial-scale AEM electrolyser for low-cost green hydrogen'' Pilot equipment is four times larger than any commercially installed anion

Techno-economic assessments of electrolyzers for hydrogen

In modeling decentralized renewable hydrogen systems, Al-Mahmodi et al. [5] assumed that AEM electrolyzers represent a potentially disruptive route to decentralized hydrogen manufacturing,

Comparative life cycle analysis of electrolyzer technologies for

Context & scale In the evolving landscape of sustainable energy solutions, hydrogen is recognized as a vital energy carrier, especially for storing renewable energy. Our

CHANGZHOU AEMHY HYGROGEN ENERGY

We have original R&D capabilities to develop materials, electrolytic cells, and systems of AEM hydrogen production, including inexpensive metal catalysts, ionomers, membrane electrodes, electrolytic

Efficient AEM Modular Hydrogen Production

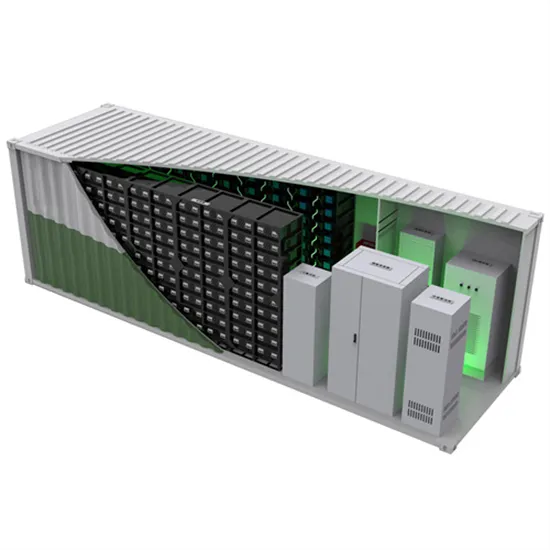

The AEM Modular Hydrogen Production System utilizes Anion Exchange Membrane (AEM) technology for efficient and scalable hydrogen generation through water electrolysis. This system produces high-purity hydrogen,

E-FUEL_AEM electrolysis water hydrogen production equipment

The company is committed to becoming the world''s leading hydrogen energy equipment technology service company.The core products are water electrolysis hydrogen preparation

Enapter begins offering its AEM hydrogen electrolysers with

Enapter, a German-Italian-Thai manufacturer of anion-exchange membrane (AEM) electrolysers, has begun selling its equipment with lithium-ion batteries to optimise the

Global AEM Electrolyser Market 2025 by Manufacturers,

Chapter 2, to profile the top manufacturers of AEM Electrolyser, with price, sales quantity, revenue, and global market share of AEM Electrolyser from 2020 to 2025.

(New Products) A Chinese Company Obtained CE Certification for Its AEM

Established in November 2021, EVE Hydrogen Energy Co., LTD. has core technologies including anion exchange membrane (AEM), AEM water electrolyser and fuel cell

Wolong Energy Storage Solutions

Flexible configuration from 70 kW to 480 kW guarantees a match with your budget and hydrogen production requirements. The modular design ensures reactivity to intermittent renewable

AEM Electrolyzers: Cost-Effective & Efficient Hydrogen Production

Discover how AEM electrolyzers combine alkaline''s low cost with PEM''s high efficiency using non-precious metal catalysts. Ideal for scalable, versatile hydrogen production. Get a quote today.

You might like this video

6 FAQs about [Aem hydrogen energy storage equipment manufacturing]

When will hygreen energy deliver a 10 kW AEM system?

ilization of hydrogen energy and demonstrates hydrogen applications in industrial parks, community buildings and transportation to create a hydrogen-powered society. Hygreen Energy’s 10 kW AEM system is scheduled for delivery to the customer in September 2024, and commissioning is expected in October 2024.

What are hygreen energy's new AEM electrolyzers?

Designed to combine efficiency, safety, and versatility in a turnkey solution, Hygreen Energy’s new AEM electrolyzers are customizable up to 100 Nm 3 /h (500 kW) of hydrogen generated, and operate across a load range of 10% to 120%. The Company’s new AEM electrolyzer system offers a range of unparalleled benefits:

Why is the AEM electrolyzer industry growing?

The AEM electrolyzer industry is experiencing significant growth due to the increasing demand for clean hydrogen production. This technology offers several advantages over traditional alkaline and PEM electrolyzers, including lower cost, higher efficiency, and faster response times to fluctuating renewable energy sources.

What is AEM pure water electrolysis?

It is considered the most advanced green hydrogen production technology and will quickly meet the market demand. The hydrogen production system of AEM pure water electrolysis with many advantages is expected to further reduce the cost, becoming the mainstream technology route product in the future.

What are the benefits of the AEM electrolyzer system?

The Company’s new AEM electrolyzer system offers a range of unparalleled benefits: Plug-and-Play Solution: Designed for ease of installation and operation, the AEM electrolyzer system comes as a fully integrated turnkey package, simplifying deployment and reducing time to market.

What does AEM stand for?

Beijing, China and Madrid, Spain – September 16, 2024 – Hygreen Energy (“Hygreen” or “the Company”), a global electrolyzer manufacturer, announces the introduction of its first-ever Anion Exchange Membrane (AEM) electrolyzer system.